Actuated valves: automation of fluid control systems ensures precision, safety and reliability.

Actuated valves are a product at the forefront of modern hydraulic engineering and play a key role in fluid control systems in various sectors and industries.

These hydraulic valves, equipped with actuators, perfectly combine mechanical precision with the efficiency of automated control. In this post, we will try to explain in a very simple way their operating mechanisms, main characteristics, applications and the main industrial sectors in which they are used.Motorised valves: how they work and what are their main features.

The heart of actuated valves is the integration of actuators, devices that convert control signals into mechanical movement. Actuators can be of different types: pneumatic, electric or hydraulic and act on the valve to open, close or modulate the flow of fluids. The perfect orchestration of these components ensures precise control, making actuated valves indispensable in automatic fluid handling systems.

The main features of motorised valves are:

- Precision and control: hydraulic actuated valves offer unparalleled precision in fluid control, enabling accurate regulation of both flow rate and pressure.

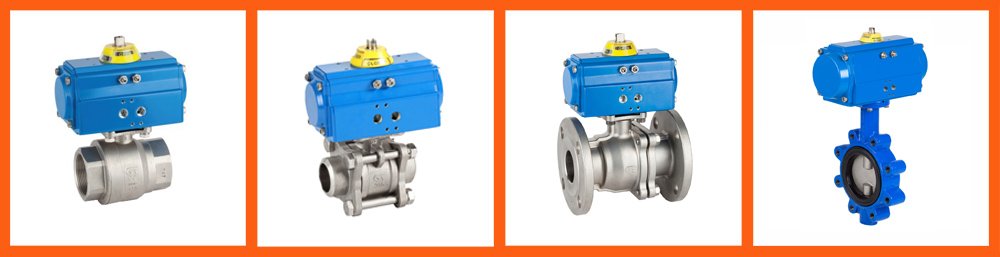

- Versatility: these hydraulic valves are available in various models, including ball and butterfly valves, and are designed to be used in a variety of environments (residential, industrial, agricultural) and with multiple types of fluids (water, chemicals, chlorinated or salt water, etc.).

- Reliability: Actuated valves boast a robust construction, which guarantees durability and longevity even under difficult operating conditions.

- Power: they are often used in contexts that handle large valves that require a certain amount of force to operate.

- Fast response: Due to their fast response times, actuated valves excel in applications where quick adjustments are essential.

Utility and applications of actuated valves.

Actuated valves find their utility in a spectrum of industries, providing indispensable solutions in scenarios requiring precise fluid control. Below are the main sectors in which they are used:

- Chemical and petrochemical industries: Actuated valves play a key role in regulating the flow of chemical and petrochemical products, ensuring safety and efficiency in processing plants.

- Water treatment: Municipal water treatment plants rely on actuated valves to control the flow of water, chemicals and other treatment agents.

- Oil and gas: in oil and gas extraction and processing, actuated valves are used to control fluids, optimising production processes.

- Power generation: Actuated valves contribute to efficient power generation by controlling the flow of steam, coolant and other fluids in power plants.

- Automated production lines: Actuated valves are integral components of automated production processes and facilitate the precise control of liquids and gases in production lines.

- HVAC systems: Heating, ventilation and air conditioning (HVAC) systems use actuated valves to regulate temperature and pressure, ensuring optimal control of the indoor climate.

- Biopharmaceutical production: Actuated valves are crucial in pharmaceutical production, where sterile conditions and precise fluid control are paramount.

- Food and beverage industry: From processing to packaging, actuated valves play a key role in controlling the flow of ingredients and maintaining quality in the food and beverage industry.

Conclusion.

Hydraulic actuated valves are now indispensable components in various industries as their efficiency, precision and reliability are crucial. As technology evolves, the role of actuated valves in the automation of fluid control processes is set to expand more and more, helping to improve not only productivity, but above all the safety of environments and operators in different sectors.