Globe 3P by Genebre: the easy-to-maintain ball shut-off valve.

A shutoff valve is generally a hydraulic valve designed to open or close the passage of a liquid or gaseous substance within a pipeline.

When using the Globe 3P by Genebre shutoff valve.

The opening or closing of the Globe 3P by Genebre valve is mechanical and requires manual intervention by an operator. The actuation may be necessary for several reasons: hydraulic risk and environmental safety (imagine e.g., the case of a water leak in a private building), emergency management (e.g., leakage of a gaseous substance in a production environment), maintenance activities (e.g., when the central body of the valve is plugged or worn and needs cleaning or replacement).

The main features of the Globe 3P shut-off valve

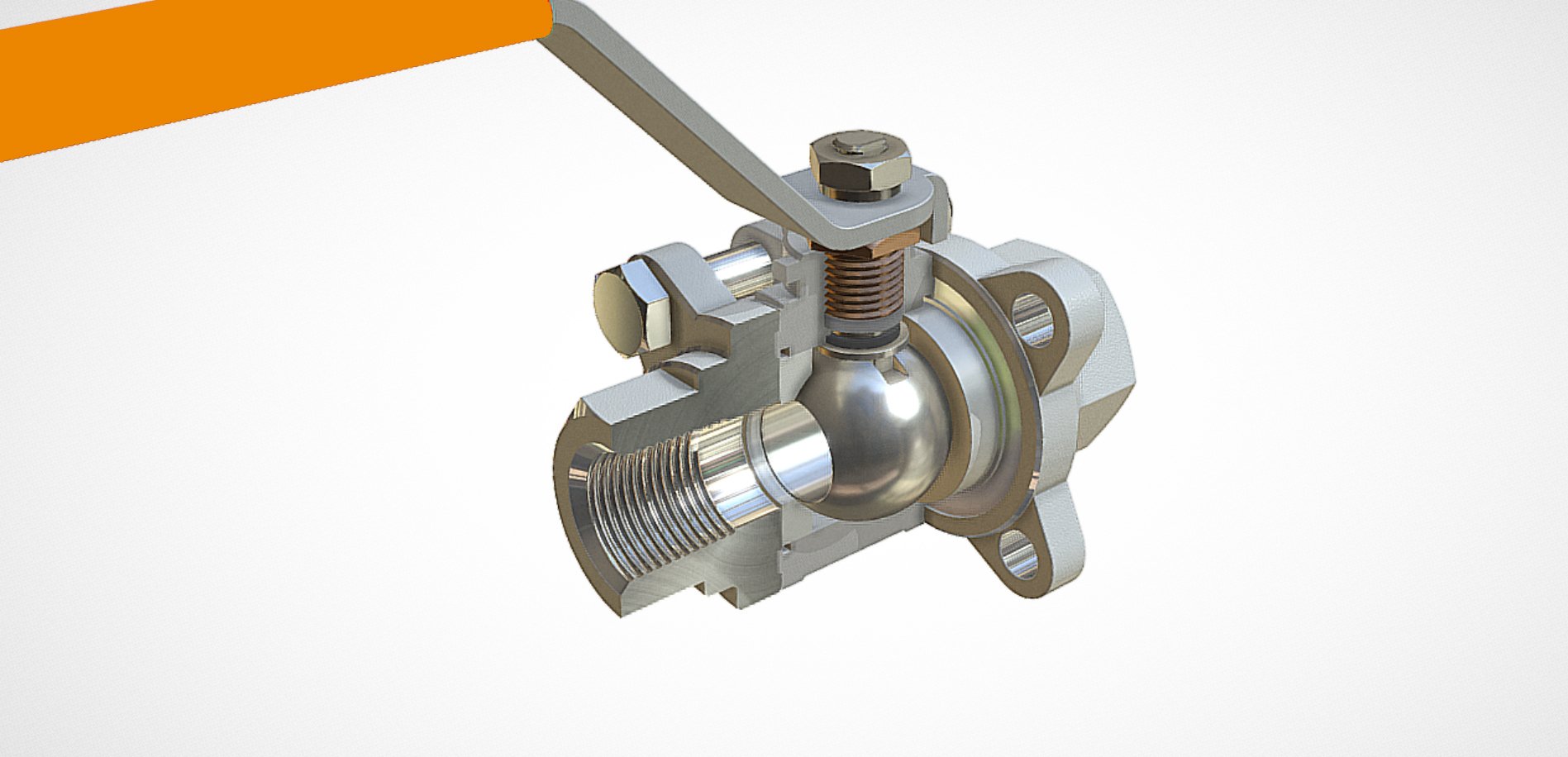

- It is made of Aisi 316 stainless steel (the body, cap, ball shutter and shaft) and this makes it particularly suitable for industrial use or in harsh environments (e.g. high salinity). In fact, this type of steel is particularly resistant to the passage of corrosive and aggressive liquids that over time could damage the valve or make its use difficult (e.g., marine areas or desalination plants but also chemicals of various kinds).

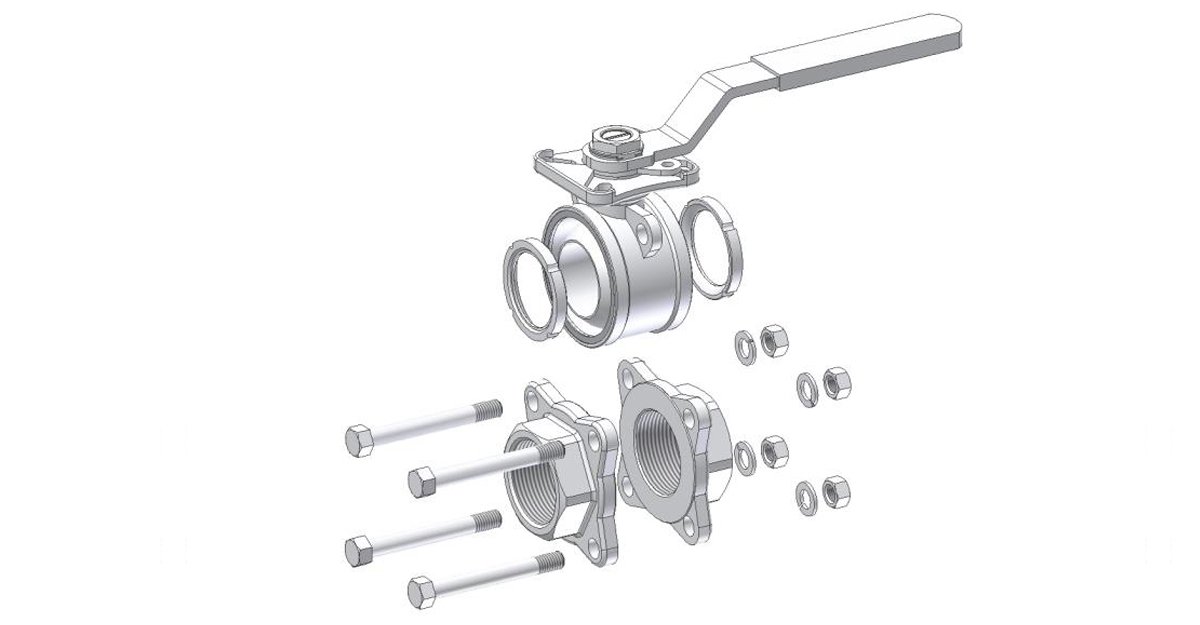

- The valve body is attached to the fittings or connections with bolts and nuts that, when disassembled, make it removable for easier maintenance or replacement (see below the exploded 3D image of the Globe 3P ball shut-off valve).

- There is a hole for attaching a security padlock just below the handle, useful to prevent accidental, malicious or unwanted opening or closing.

- Spares are available for the main and most wear-prone parts such as: ball, shaft, ball seal, gasket, shaft OR ring washer, shaft pack.

- Operating temperature: the Globe 3P, due to its high quality and construction standards, can be used in environments from -25°C to +180°C

- To automate the operation of the valve, it is possible, in some specially prepared variants, to directly mount an actuator (pneumatic or electric) on the valve according to ISO:5211 realizing a perfectly integrated solution.

Finally, we specify that Genebre's Globe 3P model has 4 versions:

- STANDARD conical (BSP thread according to UNI EN 10226-1)

- NPT (threading according to American standard conforming to the standard (Ansi B1.20.1)

- BUTT WELD (weld type with chamfered hydraulic valve connection and pipe)

- SOCKET WELD (weld type with pipe embedded in the valve fitting)

Applications of the Globe 3P shut-off valve

The features of Genebre's Globe 3P shut-off valve make it extremely flexible and suitable for various industries and applications. In the residential field, this shut-off valve is mainly applied in plumbing systems intended to last (especially in the Socket Weld version of the valve) through pressfitting application. The industrial field represents the area where the Globe 3P is particularly functional. Used with all types of connections (Standard, NPT, Butt Weld and Socket Weld) it is widely used in industrial wastewater treatment systems, chemical plants where aggressive liquids are present and compressed air systems.

Finally, Genebre's Globe 3P shut-off valve also finds application in the agricultural sector especially in fertigation systems and wastewater treatment.