Why stainless steel is a good choice when it comes to hydraulics?

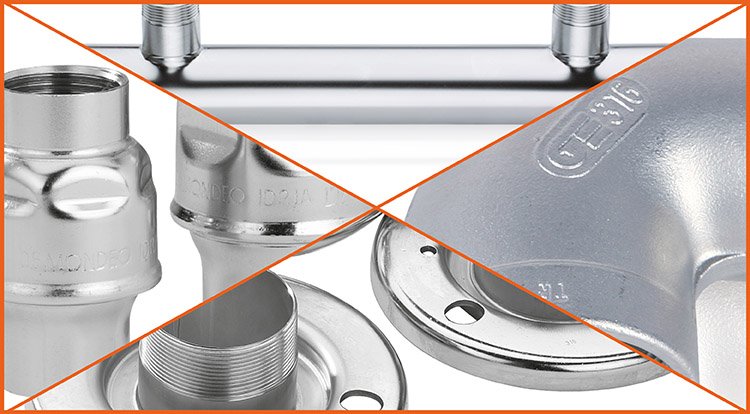

Hydraulic valves and manifolds, but also hydraulic fittings, flanges and other components made of stainless steel: designing a hydraulic system using this type of product means making a quality choice and securing several advantages.

Stainless steel is the most sought-after of steels. What makes the difference is the presence of chromium in the alloy. Stainless steel, in fact, contains between 10 and 20 % chromium, and it is this element that gives it its distinctive characteristic, namely its resistance to corrosion.

Corrosion resistance arises from passivation, i.e. the formation of an invisible film that forms naturally upon exposure to air or water. It consists of chromium oxides and hydroxides and makes the surface of the metal effectively 'immune' from the aggression of external agents.

This characteristic, moreover, can be further enhanced by electropolishing treatments. These, in fact, only amplify the passivation and thus increase the corrosion resistance of the stainless steel. The extreme brilliance that characterises electropolished stainless steel is a sign of this enhanced passivation.

All steels are not the same. Those most resistant to corrosion are the austenitic chromium-nickel steels belonging to the 300 series. Particularly well known are AISI 304 and AISI 316, which we have all heard of. Aisi stands for American Iron and steel institute, the organisation responsible for the nomenclature indicating the properties of steel alloys.

Aisi 304 and Aisi 316 are both super-strong stainless steels, 316 being even stronger due to the presence of molybdenum in its chemical composition. The use of stainless steel elements in a hydraulic system is therefore a guarantee of durability and reliability, which also translates into an economic advantage. The apparent savings given by the use of hydraulic components made of different materials, in fact, is considerably reduced by the lower performance and the need for much more frequent maintenance.

Stainless steel and plumbing applications: a healthy and sustainable choice.

Corrosion resistance also means hygiene. This is a fundamental aspect in hydraulic applications. In the food or pharmaceutical industry, in plumbing systems or in the handling of drinking water, there are high hygiene requirements that only stainless steel can ensure.

The explanation is very simple. Corrosion resistance must also be understood as inertia towards the substance with which the stainless steel comes into contact, e.g. drinking water. Inertness means that the material does not yield anything of its composition to the substance that could alter its organoleptic characteristics or cause toxicity.

Resistance also means the absence of scratches or discontinuities where bacteria can settle and proliferate. The smooth and compact surface ofhydraulic valves, manifolds, hydraulic fittings and other stainless steel elements is ideal for bacterial removal in cleaning cycles, and the absence of porosity prevents the absorption of polluting particles. Added to this is sustainability, because stainless steel products not only last longer but are also 100% recyclable!

Resistance also means the absence of scratches or discontinuities where bacteria can settle and proliferate. The smooth and compact surface ofhydraulic valves, manifolds, hydraulic fittings and other stainless steel elements is ideal for bacterial removal in cleaning cycles, and the absence of porosity prevents the absorption of polluting particles. Added to this is sustainability, because stainless steel products not only last longer but are also 100% recyclable!

The requirements that make stainless steel a super material.

In a nutshell, this is why hydraulics and stainless steel are a winning combination:- corrosion resistance

- product durability

- low maintenance

- hygiene, essential in certain applications

- sustainability.