Idrja: the stainless steel check valve for working temperatures from -25° to + 200°

IDRJA check valve: maximum hydraulic efficiency.

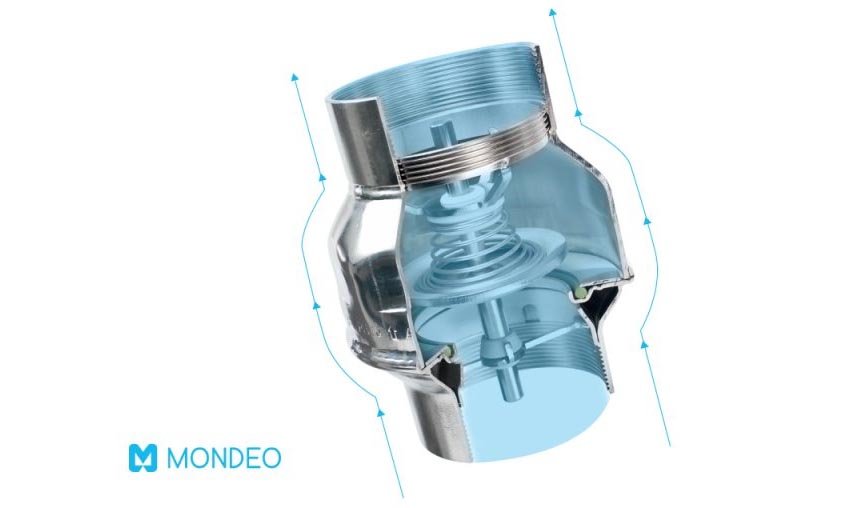

The IDRJA check valve, in its several variants, is one of the flagships of Mondeo, a Vicenza-based company that designs and manufactures hydraulic valves and manifolds of various types. Going to see the main features of this product, the first one is the realization in AISI 304 and AISI 316 stainless steel. This type of workmanship ensures maximum hydraulic efficiency and high energy savings.

The valve's large and smooth inner surface, attention to the smallest construction details, thin wall thicknesses, and TIG welds facilitate the flow of liquid and the reduction of potential causes of friction. All this generates only minimal pressure drop and consequently energy savings as these valves ensure the flow rate and pressure that are required by the system.

A note for our readers: the IDRJA check valves were subjected to a mechanical stress test in order to verify how many openings and closures they can sustain over time. The results were very interesting: over two hundred thousand activations (openings and closures) which means an estimate of uninterrupted operation of about 15 years. For more demanding systems, on the other hand, the IDRJA AC variant was created, capable of over half a million activations.

Finally, some models of the IDRJA check valves line have obtained WRAS certifications, required by the U.K., and NSF, required in the U.S.A., which guarantee the highest safety standards for drinking water treatment.

Two insights for our readers:

- The operating principle of a check valve.

It is very simple in that it takes advantage of the pressure difference between the downstream and upstream sections of the poppet: when the pressure downstream of the valve is higher than the pressure upstream, the poppet opens and allows fluid to pass through; conversely, the poppet closes and the valve prevents fluid from passing through. - The assembly of the check valve

Mounting the check valve in a hydraulic system is very simple and requires only one attention: make sure that the arrow stamped on the valve body faces the same direction as the system fluid. Incorrect mounting would close the plug causing the fluid passage to be blocked.