KIT 06N

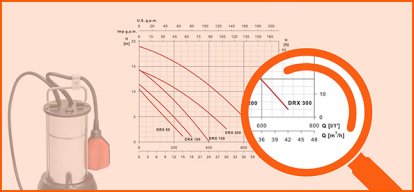

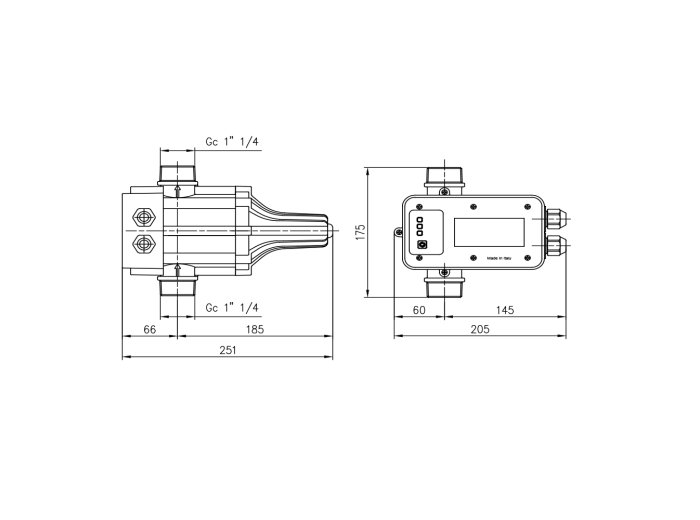

Fixed calibration pressure flow switch. Polypropylene body and cable glands, EPPM internal diaphragm, stainless steel screws (stainless steel AISI 304). In-line suction and delivery connections 1" 1/4 male. Equipped with electronic automatic start and stop device to prevent the pump from running dry, manual reset button. Reset pressure of 1.5 and 2.2 Bar depending on model. Generally, the Kit 06 pressure switch is used to control the operation of a pump by ensuring a constant pressure in the system. Ideal for pressurising small buildings and irrigation systems 16 A electronic board for electric pumps up to 2 HP, 115 V ac or 230 V ac power supply. Made in Italy, CE and TUV certified.

Key Features

Brand

ESPA

Operating pressure

Max 12 bar

Working temperature

Max 60°C

Threaded end

Gc 1" 1/4

Current

Max 16 A

Voltage

115 / 230 Vac

BUY MODEL VARIANTS

In this section you will find all the variants of this model in the catalog: you can use the filters below to make your search more specific. When you have identified the variant you need, specify the quantity and use the button to add it to your Shopping List.

Loading...

Type of power supply:

AC

Number of phases:

1

Motor Frequency:

50-60

Min. working flow (Q min):

1,00 l/min

Min. working temperature:

5,00 °C

Max. working temperature:

40,00 °C

Type of fluid treated:

Clear Water

Min. ambient temperature:

5,00 °C

Max ambient temperature:

50,00 °C

Max. ambient humidity :

50

IP insulation grade:

IP65

Voltage tolerance:

+/-10%

* Note:

dimensions are expressed in millimeters (mm.), unless otherwise specified.