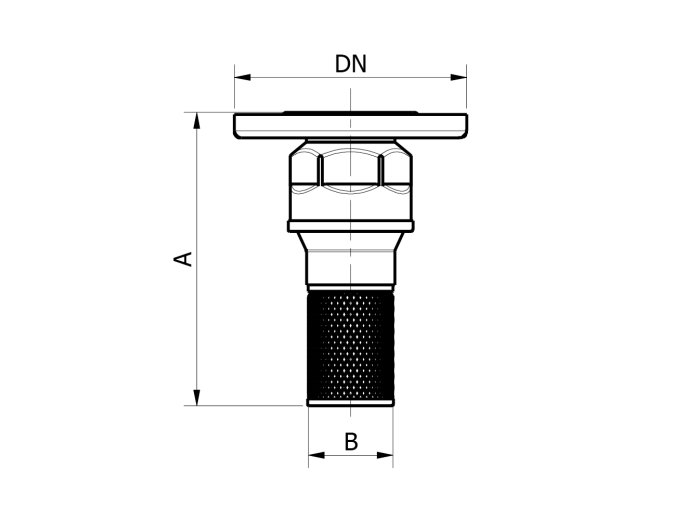

IDRJA FLANGED FOOT VALVE

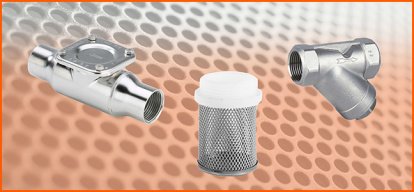

In-line check or non-return valve made of stainless steel (stainless steel Aisi 304 or Aisi 316). Spring-loaded closure and reinforced leaf with FPM seal. Pressed stainless steel flanged connection according to UNI EN 1092-1 on delivery side and stainless steel filter (stainless steel Aisi 304 or Aisi 316) on suction side. Surface treatment: degreasing, pickling and electropolishing. The IDRJA/DI FONDO check valve is generally used in civil and industrial hydraulic systems in the inlet position where it is necessary to filter the fluid and operates at a nominal working pressure (PN) of 16 bar.